Automation is the future of CNC

Automation for all

Automation is the future of manufacturing. And it doesn’t have to be a distant future.

At Okuma, we work to equip shop floors with the perfect machine and automation pairing. Whether you’re beginning your journey or ready for the next step, we are here for you.

Automation Benefits

See for yourself what all the automation

excitement

is about

-

Tackle more work

With continuous machining, even during ‘non-operational’ hours, ROI is greatly enhanced

-

Increase Profits

More output, proper resource planning, and decreased labor costs lead to lower cost per part

-

Shorten Lead Times

Manufacturers can deliver quicker due to the extra hours of fully automated manufacturing

-

Reduce Scrap

Reducing human interaction provides greater consistency and lowers error rates

-

Attract Talent

Appeal to and maintain higher skilled workforce with engaging tasks, ergonomics, and safety

-

Save On Utilities

Overhead costs such as lighting, HVAC, and even floor-space requirements can be reduced

Lights out — 24/7

You may be tired, but your automation is not. By leaning into automation solutions, shops around the globe are realizing the most profitable span of time can be when no one is physically located on the floor, yet the machine tools continue to run.

Learn More

Automation Categories

We partner with the best.

Wanting to pull automation into your workflow? Know you're not alone in figuring out the best path forward. At Okuma, we work with trusted automation partners to ensure full harmony with our high-quality machine tools.

-

Bar Feeders

LEARN MORE →- Simple addition to most Okuma lathes

- Great for low-mix, high production manufacturing environment

- Affordable, entry-level automation to boost productivity

-

Automatic Pallet Changers

LEARN MORE →- Perfect for vertical lathes, machining centers, and double columns

- Choose from in-machine, single-level, or tower APCs

- Provides hours of unattended machining

-

ROBOTICS

Okuma Robot Loader Series

LEARN MORE →- Set up in less than 10 conversational steps (speeds deployment and minimizes training)

- Pre-programmed, so no previous robotic experience is required

- Designed for fully automated, unmanned operation

-

Okuma Gantry Loader Series

LEARN MORE →- Integrated design enables precise part-processing speeds, which result in reduced cycle times

- Supports part weights from 5kg to 150kg and shapes for optimal versatility

- Perfect for repetitive production needs

-

Flexible Manufacturing Systems

LEARN MORE →- Seamlessly automate numerous machines, even different models

- Configured to manufacture a variety of parts

- Able to adapt and handle changing levels of production

- Setup consultation, configuration, and installation available

-

ROBOTICS

Pre-Kitted Automation Cells

LEARN MORE →- Pre-configured automation packages

- Easy to integrate, quick to implement

- Kits designed for all machine tool categories

-

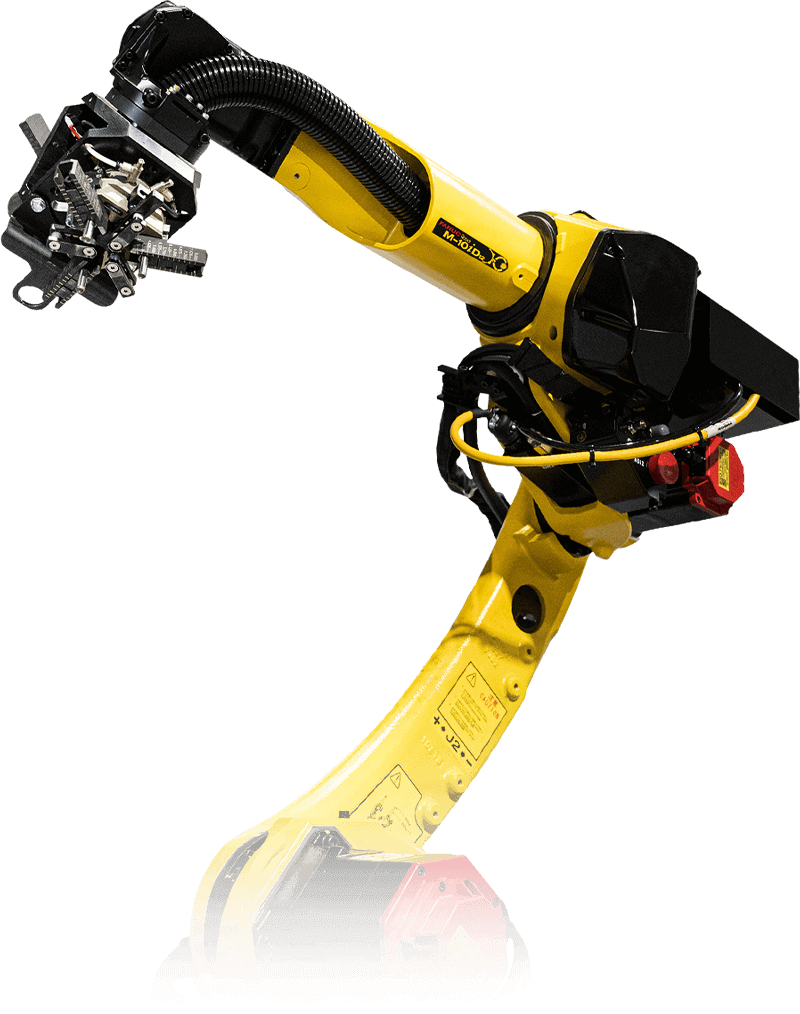

ROBOTICS

Industrial & Integrated Robotics

LEARN MORE →- Pre-engineered solutions for straightforward integration

- Configuration flexibility for specific applications

- Combine with smart manufacturing software for insights

-

ROBOTICS

Cobots

LEARN MORE →- Okuma integrates with a wide range of collaborative robots

- Customizable programming, speed, and safety settings

- Intelligent features for insights into smart manufacturing

-

ROBOTICS

Okuma ROID Series

ARMROID → STANDROID →- OEM built-in and standalone robot packages

- Single panel controls machine and robot

- Part loading/unloading, chip removal, and more

Automation Statistics

Automation is making a huge impact for those that embrace it

Robotic automation increases the utilization of your equipment by

200 to 400%1

You can shorten lead times and offer better quality at

30% less cost by using automation1

A CNC machine shop that employs robotic automation manufactures

47% more parts-per-hour2

When you add in automation, machine utilization increases from

2,000 to 6,000 hours per year3

With the right choice of robotic automation, your direct labor costs can be reduced

by 50 to 90%1

Okuma's Dream Site showcases lights out manufacturing with

100% productivity increase,

50% cut in lead-time,

30% electrical costs savings4

Resources

Automation Knowledge Center

CNC (computer numerical control) automation refers to integrating automated systems and technologies into CNC machines to perform specific tasks in the manufacturing process. Automating repetitive or time-consuming tasks, such as loading and unloading parts or changing machine tool parts, helps enhance efficiency, productivity, speed, and precision with minimal operator oversight required. CNC automation also enables 24/7 machines — including mills, lathes and drills — to operate continually for optimal uptime and production.

There are three main types of automation used in manufacturing. Fixed automation uses specialized equipment for high-volume, repetitive tasks during long production runs of identical products. Programmable automation is primarily used during batch production, where runs are repeated, but the setup changes for different types of products. Flexible automation can quickly and easily switch to different products and production volumes without significant reconfiguration or unplanned downtime.

Automation can increase productivity and operational efficiency, helping manufacturers stay competitive in modern manufacturing environments. Okuma Flexible Machining Center (FMC) solutions include robots, cobots, automatic pallet changers, bar feeders and gantry loaders.

Lights out manufacturing (LOM) refers to a highly automated manufacturing production environment where operations run autonomously and continuously (often 24/7) with minimal or no machine operators present. The goal of LOM is to achieve maximum productivity and reduce downtime.

In CNC machining, automation offers several key benefits increased productivity (tasks can be performed autonomously and continuously), improved precision (minimized human variability), reduced labor costs (fewer machine operators are needed), lower lead times (shorter setup times maximizing production cycles), and enhanced safety (reduces operators’ exposure to repetitive motions and potentially hazardous tasks).

Automation is not intended to replace machine operators, but integrating automation into manufacturing may shift some personnel roles and responsibilities. For example, automation may perform repetitive and time-consuming tasks, like loading and unloading materials. However, technicians are still critical in overseeing the automation process, troubleshooting potential issues, and performing regular maintenance for enhanced quality control and operational efficiency.

All industries can benefit from CNC automation, particularly those that require high-precision and high-volume production, such as aerospace, automotive, valves, electrical manufacturing equipment, and metalworking.

CNC automation is the future in manufacturing, with the industry quickly moving toward greater integration of automation solutions. This shift will drive the evolution of manufacturing into digital- and AI-driven, self-optimizing environments where machines operate more efficiently. As automation becomes more scalable and adaptable, manufacturers will increasingly be prepared to respond faster to market demands and enhance productivity.

Get started on your automation journey today.

Cited Sources

1. Cutting Tool Engineering. CNC Automation: Should We?

2. Motion+Drives. 10 Reasons to Add Robotic Automation to Your CNC Shop.

3. Fastems. Automation Makes Manufacturing Competitive and Sustainable.

4. Protolabs. Data, Digital Threads, and Industry 4.0

FANUC ASI CERTIFIED

Okuma is proud to be a trusted FANUC Authorized System integrator (ASI). Experienced in implementing integrated automation solutions to meet our customers' needs, Okuma has the knowledge and expertise to provide systems ensured to improve quality, throughput, and productivity.