The Power of the Multitasking Process

David Fischer 08.06.2020

The ability to perform multiple machining processes on a single machine can be a game changer for many shops. When you have a machine that’s capable of machining complex parts without the need for constant operator oversight, jobs can run more quickly, precisely and efficiently. Discover all you need to know about multitasking machines.

WHAT IS A MULTITASKING MACHINE?

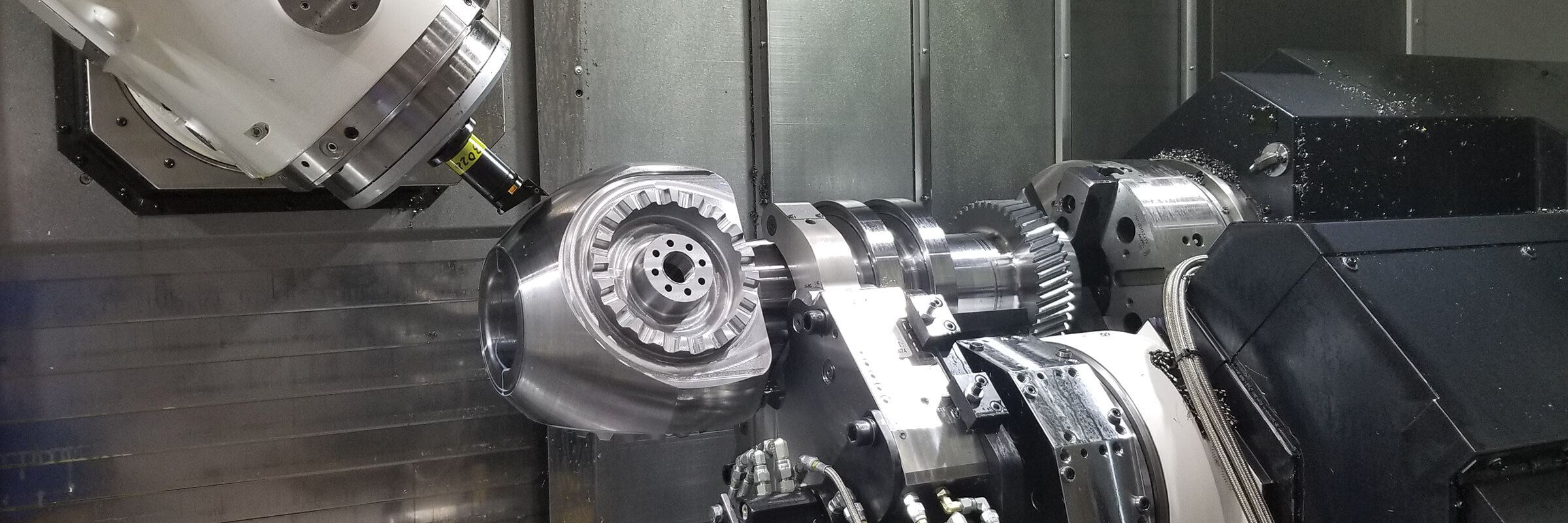

A multitasking machine combines the manufacturing capabilities of milling machines and turning machines into one integrated unit so you can use the functionality of both simultaneously.

This type of machine is often viewed as the machine equivalent of a Swiss Army knife - though both are equipped with all the tools you could want, there are a few reasons the comparison falls short. On a Swiss Army knife, functionality is limited to using one tool at a time, and the tools available on a Swiss Army knife are never preferable to a full-size version of the same tool.

On a multitasking machine, however, all the tools available are integrated, and that integration means there are even more capabilities than with those tools on their own. Also, on today’s multitasking machines, you no longer have to sacrifice turning or milling capability. Both are just as capable as conventional machines of that type.

ADVANTAGES OF MULTITASKING MACHINES

For manufacturers who need to be agile, multitasking machines feature functionality to suit a wide variety of applications. This is particularly beneficial for job shops, whose manufacturing requirements are constantly changing and need to be prepared to quickly pivot from one task to another.

Mass customization is another benefit of the multitasking process. In low volume, high product mix environments where your customers' requirements are constantly changing, there needs to be a large capacity for flexibility, one that a multitasking machine can provide.

In order to achieve maximum capacity efficiently, multitasking machines allow you to reduce or even eliminate setups and also help decrease fixturing costs. Multitasking machines are not limited to producing simple parts – there is a wide range of complex parts that a multitasking machine is capable of producing.

The multitasking process also limits the amount of human intervention required in manufacturing. With reduced operator error, improved labor efficiency and part accuracy, operators are allowed to focus on more complex, critical thinking-related tasks while the machine continues to operate efficiently.

THE MULTITASKING PROCESS

The conventional manufacturing process varies by part configuration, but can include multiple operations on multiple machines, including turning and machining center operations. On a multitasking machine, this can be reduced to one machine and one automated transfer – the only necessary operator intervention involved is loading the raw material in the beginning and removing the finished part in the end. Changeover of jobs on multitasking machines can be extremely fast, since the tooling is quick-change by design and the workholding is typically limited to two 3-jaw chucks. Having to interrupt a job to process a hot job is no longer the major headache it is on a conventional process. Quickly change over to the hot job and once it is complete it can be restarted on the original job.

Moving to the multitasking process also removes the need for fixtures and non-quick change tooling. All tooling is quick change and the need for setup of machining center fixtures and rotary tables is eliminated.

Want to learn about the multitasking process in action? Contact your distributor to request a demo of the MULTUS series, Okuma’s multitasking machines.