Are You Keeping Machine Tool Event Logs?

10.24.2017

Ever try to get an issue fixed on your machine tool, but the issue never shows up when the service tech is present? This can leave you feeling like it will never end, taking away from production, adding multiple trips from the service reps, and leaving distrust amongst those involved. So how do you try to nip this in the bud? Event logs! They might seem like a waste of time, but the information can be invaluable to you and the service tech who’s trying to help you.

Shortcut to the Solution

As an example, consider the machine tool that only gives an alarm every 3 hours exactly, and the skimmer hooked up to the machine timer is set to the same amount of off time. A specific sequence of button pushes might show a software issue. Only the night shift has the insert blow up on tool 3. The operator crashed the machine. All of these examples I personally have had, and because someone took the one minute to record them, I was able to fix something next to impossible at the first crack.

Start with the Basics

You might think “My machine records everything, and a good tech wouldn’t need that”. Well, not so. Very few service techs know that two weeks ago there was a thunderstorm in your area, lightning struck a transformer, and all the machine(s) in the shop had some weird thing pop up right away or a few days later. So what information should be recorded? Well the best answer is no detail is too small, but human nature will say only the most relevant details. So as a base, start with these:

• Date

• Time of day

• Alarm(s) (sometimes there are more than one)

• What was observed?

• Picture of event or video

• Other things that happened in the shop around that time

This information should be shared with the distributor service department so they can try to diagnose the machine before they come to your shop. This enables your tech to arrive with the most likely part/service tools needed, plus a service tech who is best suited for the issue can be dispatched for your job.

Set Up an Event Log Process

When to record? Well that’s up to you but a good start is every time something happens that the operator believes should not have. So, a tool changer stuck, the machine kicked me out of the screen I’m in, the machine hesitated, or even, I had a bump or crash. One easy way to do this is to create a Word document saved on the network in a folder labeled “Event Logs”. Or old school pen, paper, and a book glued to the side of the machine. Don’t forget your pictures. Everyone has a cell phone that takes pictures these days. Plus, with the Windows control, fn prt screen does the same thing.

Event Log Examples

To help you envision the process, here are a few examples of event log entries.

June 12, 2017 1:00 am; alarm p 13 interrupt error:

Machine went dim, then turned off, and when it came back on it had this alarm. Pressed reset and kept going. Compressor in the shop is loud tonight.

July 11, 2015 8:12 am; no alarm:

Machine booted up fine, but went to open the doors, and CAS is still loading. Waited 10 minutes, gave up, and turned it off. Happened last Monday too. Screen blurred like a paint brush stroke.

July 12, 2015 12:00pm; in house maintenance manager replaced batteries

July 22, 2015 2:22am; no alarm:

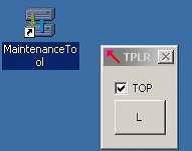

Turned on machine now I have this icon at boot up.

December 10, 2013 3:18pm; u-drill inserts blew up, has MCS alarm 1170-40.

A Habit I Personally Recommend

I share these thoughts based on my personal experience in the field. It’s good to make a habit of keeping event logs. They’re an extremely useful resource when you - or your service technician - need to troubleshoot a machine tool.

Thanks to Kirk Quast (Senior Service and Applications Engineer, Thomas Skinner) for providing this article.

We offer a variety of ways for you to stay informed about our events, and to receive general Okuma updates. Fill out the form below to let us know the type of information you'd like to receive.