OSP-P300 CNC Control Delivers Process Efficiencies and Enables User Innovation

11.14.2013

Executive Summary

Okuma’s history of introducing innovations in CNC control technology spans more than 50 years – and the OSP-P300 is the latest breakthrough. The OSP-P300 brings a dramatic paradigm shift to the marketplace, with a process-based user interface rather than the traditional mode-based operational layout. The process-based platform is most evident in the EASY OPERATION interface, which centralizes data in one easy-to-access screen, displacing the cumbersome process of back-and-forthing through five or six screens. By streamlining process efficiencies, productivity is greatly increased.

The OSP-P300 is built using the Windows®-based, open architecture platform used in all OSP-P CNC controls. This fully open system makes it possible to easily install PC applications that allow for a multitude of conveniences. For example, users can set up access to tooling lists/setup spreadsheets, process documents, and how-to videos that assist operators in setup and operation – right at the CNC machine location. The OSP-P300’s open architecture platform also opens the doors for users to continually customize operations to suit individual CNC machining requirements.

Okuma is the industry’s only single-source provider, with the CNC machine, drive, motors, encoders, spindle and CNC control all manufactured by Okuma. By having mechanical and electrical under one roof we can ensure optimum production efficiencies, and also provide ways for customers to customize processes (for example, with custom app development).

When users experience the efficiencies of the OSP-P300, there’s no going back to the old, repetitive and time-consuming way of CNC control operation. And, because the open architecture OSP-P300 allows users to create their own innovations, this opens up countless opportunities to deliver added value in products, implement manufacturing efficiencies that increase productivity, and establish a competitive edge in the marketplace.

DOWNLOAD THIS WHITE PAPER

This white paper is also available as a free downloadable PDF. Or, you can continue reading it below.

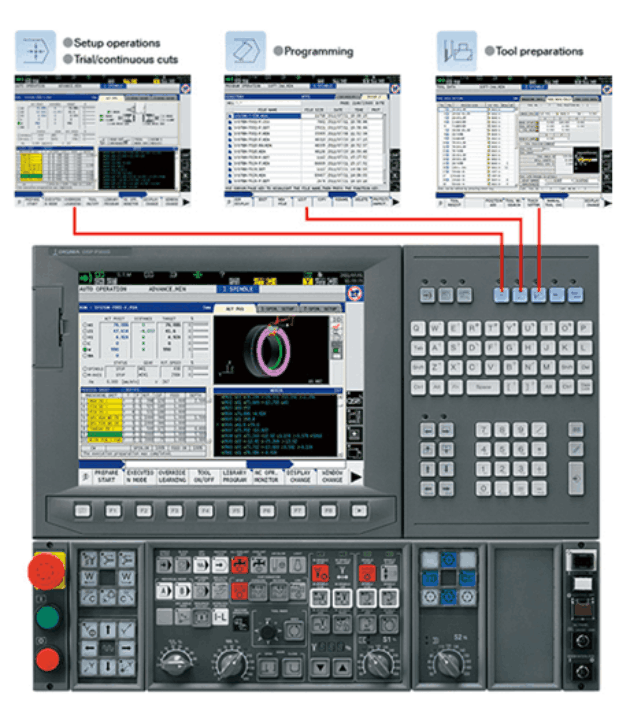

EASY OPERATION RUN SCREEN

One of the most compelling innovations from a user standpoint is the OSP-P300’s EASY OPERATION run screen (see Figure 1). This feature centralizes all operator functions into one single screen, and is customized for the CNC machine’s unique operation workflow. Simply select one of three operation screens:

- Setup Operations or Trial/Continuous Cuts

- Programming

- Tool Preparations

Then, all that’s required is to touch the screen or press a function key to setup, run and monitor the job. Tool data is shared with other control functions, so it only needs to be created once. EASY OPERATION also expands the manual machine operation functions, and only creates tool offsets for the positions the operator uses.

Following are a few of the processes that are simplified and streamlined by the EASY OPERATION run screen:

EASY TOOL PREPARATION

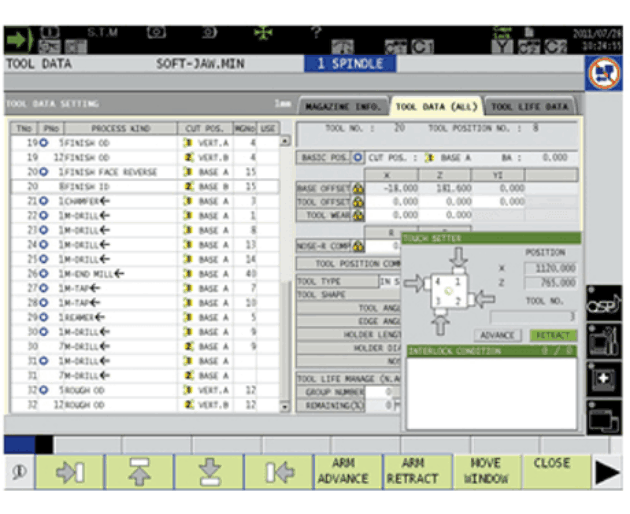

Tool Registration

Data is registered for all tools. Since the registered tool data is also used by Okuma auto programming (Advanced One-Touch IGF) and a collision check function (Collision Avoidance System), the entire registration process is completed in this single screen (see Figure 2).

Tool Mounted on Machine or Tool Change

After loading a tool into the machine, simply select it from the registered tools. Automatic Tool Changer manual operation does not require inputting the tool number. Simply select the tool from the list and press the function key (see Figure 3).

Tool Offsets

By pressing a function key while watching the graphic guidance, the tool is brought into contact with the sensor and the tool compensation value is set (see Figure 4).

EASY MACHINING PREPARATION

Forming Soft Jaws

Templates make it easy to set jaw shape, tool, and cutting conditions (see Figure 5). Part programming is not required.

Zero Offsets

A simple function key operation is all it takes to shift a zero offset to either the left or right end of a workpiece (see Figure 6). The required zero offset is calculated automatically based on jaw and workpiece lengths (when the tool offset is set with reference to the turret tool mounting surface).

EASY MACHINING DISPLAY

Operation screen split into four displays

Four simultaneous displays show setup work, current position NC program, and graphic simulation needed for confirming movement in trial machining (see Figure 7).

SHARED DATABASE ELIMINATES REDUNDANT DATA ENTRY

On the programming side, the key to the OSP-P300’s easy operation is its new shared database. This is a radical difference from other controls on the market. With a single database, operator inputs are shared amongst all control functionalities. This means data that is input in one area of the CNC control is automatically shared in other areas. For example, when the operator sets up tools for typical CNC machine functions, they are entering data. Then if they want to take advantage of Collision Avoidance (CAS) or Advanced One-Touch IGF, these new tools are automatically connected to the original data set. No new data entry is required, the new tools are ready to use, and operators can focus on making parts instead of getting bogged down in redundant data entry (see Figure 8). The bottom line? Fewer keystrokes and faster setup times.

ADDITIONAL “EASY” FUNCTIONALITY

There are many other enhancements to the OSP-P300 CNC control that make it easier to perform certain tasks, such as:

- Manually clamp the c-axis with the push of a button

- Rotary switch manually indexes the B-axis (multi-tasking machines) every 45 degrees

- Index the lathe tool with the push of a button

- Makes all the Stop Operation buttons red on the control panel for easier viewing

- New feature to select and change tools from manual mode

THE INDUSTRY’S ONLY NON-PROPRIETARY CONTROL

The OSP-P300 is built using the Windows®-based, open architecture platform used in all OSP-P CNC controls. This fully open system makes it possible to easily install PC applications that allow for a multitude of conveniences. For example, users can set up access to tooling lists/setup spreadsheets, process documents, and how-to videos that assist operators in setup and operation – right at the CNC machine location. A USB caliper or micrometer can be used to measure parts and electronically capture statistical process control data right on the CNC control – eliminating the cumbersome (and sometimes inaccurate) challenges of the paper trail. The OSP-P300’s standard Ethernet and multiple USB ports allow for easy integration between the factory floor and ERP/MES systems.

MTCONNECT AND OPEN API ALLOW USERS TO CREATE CUSTOMIZED APPS

In the spirit of the completely open control, Okuma offers the API associated with your OSP-P300 control free of charge. This allows users to write customized PC-based applications (apps) that can communicate with the control to get data in and out, read and write code, and set parameters and variables for tool information. All Okuma CNC controls include the APIs – they ship standard with the machine and allow full read/write access to over 6,000 data points. In addition, Okuma is a leading member of the MTConnect Technical Advisory Group (MTCTAG) and fully supports the implementation of MTConnect-based applications.

For examples of apps that can be created for the OSP-P300 control, see our blog post “10 Tricks You Can Teach Your CNC Control.”

YOUR COMPETITIVE EDGE

Through the years the OSP control has continued to evolve, and the OSP-P300 is our latest innovation. By transitioning to a process-based mode of operation we allow users to streamline control operations and also to create their own innovations. This enables our customers to deliver added value in products, create manufacturing efficiencies that increase productivity, and establish a competitive edge in the marketplace.

LEARN MORE

For more information about the OSP-P300 and the products on which it is available (Okuma lathes, vertical machining centers and horizontal machining centers) check with your local Okuma Distributor, or contact us.