The Meeting of Minds + Machines

Paul Russell 01.11.2017

Recently I had the pleasure of participating on the team representing Okuma at GE’s Minds + Machines event. This is billed as “GE’s premier Industrial Internet event dedicated to software, innovation and the most powerful digital industrial outcomes,” so it was an honor to be the only machine tool builder exhibiting.

The entrance to the Minds + Machines event, held in San Francisco

We set up a GENOS M460-VE vertical machining center with the goal of demonstrating machine tool connectivity and the benefits of using GE Digital’s Predix operating system for the Industrial Internet on Okuma CNC machines. In order to show an interesting part being made from start to finish we “manufactured” coins that we gave away to attendees. We used this manufacturing process to demonstrate how Predix is used to monitor key metrics that affect productivity. Because Predix allows users to visualize machine data, potential efficiency roadblocks can be identified and managed.

Here are the coins we made using GE Digital’s Predix on an Okuma GENOS M460-VE

READ THE PRESS RELEASE: Okuma Collaborates with GE Digital to Connect Manufacturing Machines to the Industrial Internet

Easy Connectivity

Okuma’s OSP-P300 control is a natural fit for the Predix platform because it was designed, from its inception, as an open architecture, Windows-based controller that provides user-friendly, easy connectivity. The P300 provides an additional advantage because we can load Predix right on the control, without additional interfaces or hardware. At the show we loaded Predix on our control, configured it, and started collecting data all within a half hour. We utilized MTConnect, an industry standard for data collection, to pass the data from the OSP control to the Predix dashboard.

This screenshot of Okuma’s OSP control shows data streaming on the GE dashboard

Maximize Machine Utilization

All of the data that’s streamed from the OSP control can be viewed on the Predix dashboard. For demonstration purposes the dashboard GE used showed data such as cycle time, part counts, part program name, alarms, spindle and axes loads, etc. The dashboard interface can be customized to view whatever data the user wants to see. While data acquisition certainly provides handy tools like counts, perhaps more importantly this data is crucial for shops that want to increase machine utilization, because metrics reveal areas that must be addressed.

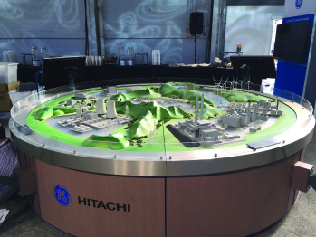

The event was full of cool technology like this display of GE’s nuclear/wind/power generation plants which demonstrated how they monitor these facilities with Predix

Predix is Predictive

By embedding Predix on Okuma machines, Asset Performance Management (APM) tools can be created so companies can move from alert-based interactions to prescriptive, analytic real-time solutions. When you’re taking actions based on the prediction of outcomes, you can manage and control the results. This is opposed to the reactive stance one takes when simply responding to alerts, where a negative outcome may have already occurred.

This meeting of “Minds + Machines” demonstrated the synergy of the partnership between GE and Okuma. In this case, great minds are thinking alike as we enable manufacturers to evolve and profit by leveraging the Industrial Internet.

Paul Russell is Applications Engineer, Okuma America Corporation.