Machine Tool Apps: A Manufacturing Definition

02.19.2015

Executive Summary

In 2008 both Apple and Google launched their versions of the now famous App Store. In seven short years apps have become integral to our everyday lives, providing indispensable conveniences on smartphones, tablets and other devices. Today the saying “there’s an app for that” is true – there is an app for everything. Why do we love apps? Bottom line, they make our lives easier. And many apps (such as GPS navigators, flight status notifiers and fitness trackers) increase our personal productivity.

Now “machine tool apps” are entering manufacturing environments, and they will become pervasive productivity enhancers there as well. As apps make their way onto shop floors it’s important to define, for the machine tool industry, what an app is (and what it is not). This is critical for establishing a foundational app environment that is open to customization by anyone, and can therefore meet a shop’s unique requirements. Here we will cover some of the key qualifying criteria that define a machine tool app.

DOWNLOAD THIS WHITE PAPER

This white paper is also available as a free downloadable PDF. Or, you can continue reading it below.

MACHINE TOOL APP: CORE DEFINITION

A machine tool app is a piece of software that streamlines or simplifies operations on a CNC machine and its control, providing enhanced productivity. It is a self-contained program written for a very specific functionality. Because of the dynamics of the manufacturing environment, openness to customization is a crucial feature of any machine tool app. Just like a smartphone app, a true machine tool app is built on an open platform that can be customized by the user or any third-party developer (e.g. machine tool accessory providers, operators, programmers, or IT specialists).

A machine tool app can be accessed in a variety of ways: on the CNC control, on a laptop/desktop computer, via tablet or smartphone. Therefore these apps can connect and extend throughout the business and even into the user’s personal life. Machine tool apps are an open and mobile technology that is designed to make manufacturing easy.

PRACTICAL BENEFITS OF MACHINE TOOL APPS

Okuma’s App Store is the industry’s only centralized online marketplace for machine tool apps and related content (see Figure 1). The App Store contains not only apps developed by Okuma, but also apps from our distributors and various members of Partners in THINC.

From Okuma’s App Store, users can download apps that provide significant productivity-enhancing benefits such as:

- Reduce Scrapped Parts: Many apps are designed to avoid the high costs associated with scrapped parts. For example, Part Flip Monitor is used for CNC lathe operations where a part is machined on both sides using a single spindle. Part Flip Monitor clearly displays “first side running,” “part flip needed” or “part completed,” so the operator can tend to other machines while keeping track of the lathe’s progress.

- Reduce Downtime: Proactive maintenance is one of the best ways to eliminate the costly disruptions of unplanned downtime. The Scheduled Maintenance app gives users the opportunity to display a daily reminder of inspection tasks that should be performed prior to running the specific machine where this application is installed. And Coolant Monitor is used to monitor coolant concentration level and send a warning to the operator if action is needed. The result is “planned uptime.”

- Diminish “Labor Pains”: Many shops struggle with shortages in their skilled labor pool, and machine tool apps can help fill this gap. There are machine tool apps that provide handy guidance, right at the machine tool, that makes it easier to learn processes and run jobs. An example is Caron Engineering’s AutoComp, which adjusts tool offsets based on dimensional data from any number of gauging devices, taking the guesswork out of compensating the machine.

- Maximize Use of Consumables: There are machine tool apps that proactively monitor consumables by alerting the user to issues involving things like tool life management and coolant monitoring. This allows users to maximize these assets and replenish them at the point of complete utilization, and prior to failure.

- Increase Part Quality: Nearly every machine tool app increases overall part quality. With the Blum Gauging Guide and Renishaw GUI apps (which guide users through simple and logical steps to program gauging), part quality can be increased without adding time-consuming manual protocols.

- Increase Productivity: Tool selection calculators and configurators help the user select tools and determine feeds and speeds, increasing productivity of the workers and improving overall shop performance. And with more apps to come, productivity will continue to improve.

- Enhance Ease-of-Use: Delcam’s Partmaker Viewer improves visualization right at the machine and reduces the chances of errors. With machine tool apps, it doesn’t have to be hard, time-consuming or complicated to increase productivity. Every app in the Okuma App Store makes processes easier along the way.

THE MACHINE TOOL APP EVERYONE WANTS

As shop owners and operators explore the array of apps that are already available for use, there’s a clear favorite that most want to download right away. Machine Alert allows the user to set up machine alarms that are sent by email or text message directly to their mobile phone. Clearly this holds significant appeal in that the user, from any remote location, can ensure that a machine is running, 24/7, and provides peace of mind that chips are being made without interruption. If there is an interruption, the Machine Alert notification allows them to take action and solve the problem immediately, preventing costly downtime.

“FAST TRACK” TO PRODUCTIVITY GAINS

Many users think of the controller as simply a set of buttons for the machine itself. Yes, its primary function is to act as the brain of the machine tool, and is used for setting and monitoring cutting programs. But the control is much more than that. It’s actually a computer, and just like a desktop PC/Mac or laptop, it can deliver many other functionalities such as Internet access, integration with stored programs, and connection to business systems. As a computer, your control can serve as a place to store machine tool apps that enhance productivity. In fact, using apps on your control is one of the simplest, fastest ways to make significant productivity gains, quickly.

APPS MAKE YOUR OKUMA “MY OKUMA”

Okuma’s App Store is located at www.myokuma.com, and “My Okuma” is an important distinction. Consider what happens when you purchase a smartphone. Out of the box, each phone is identical. But soon you install apps that you use most often. If you’re a frequent traveler, this may be the app from your preferred airline. You might add your favorite weather app, and perhaps one from your local bank. At this moment the generic smartphone becomes your personalized device, loaded with the specific functionalities that make your life easier.

The same is true for your Okuma machine tool. Once it’s in your shop, you can install the apps that suit your particular needs. Instead of your favorite weather app, perhaps you have a favorite tooling provider, such as Kennametal. In the App Store you can find a Kennametal app called NOVO that optimizes your productivity every step of the way — from parts quoting through programming, presetting, and production. If you’re a Sandvik user, there are three Sandvik calculators to choose from. Just as your smartphone becomes individualized when you add your favorite apps, your machine tool becomes “My Okuma” when you download apps that suit your individualized needs and desires.

OPEN ARCHITECTURE: GATEWAY TO COMPLETE ACCESSIBILITY

The reason apps have become so useful in our personal lives is because they’re based on an open development environment. This has spawned app proliferation (so many to choose from!) and stimulated app innovation (anyone can create one for their own unique needs).

Openness is the reason “there’s an app for that” today.

Therefore an open architecture control platform is the basis for true machine tool apps. The rich opportunity presented by machine tool apps will never be fully maximized in a closed control environment. What is a closed environment? An example is pre-packaged, off-the-shelf screen “shortcuts” that pose as apps but do not offer the freedom to customize what’s needed for a shop’s unique processes. Thus thwarted, users would never realize the full productivity potential that can move their business forward. And, if limited to a closed control environment, the industry overall will suffer lack of opportunities for significant growth.

BEWARE THE SHORTCUTS (WHAT IS NOT A MACHINE TOOL APP)

The true definition of a machine tool app must state that the environment is open for customization by individual users. Whenever a user is purchasing a machine tool, a key question to ask is “can I write my own apps for this control?” There are some machine tool builders that have truly open architecture controls that allow for individual customization, and Okuma is one of these. Okuma’s OSP-P control is Windows®-based, which allows for ease-of-use and integration with other programs. Most of the big CNC builders do not offer an open architecture platform. They might provide an interface layer on the control that gives users shortcut tools for their own preprogrammed functionalities. But these kinds of shortcuts are short-lived in their apparent usefulness and will need to be endlessly modified by the CNC builder to match the unique needs of each individual machine shop, both now and in the future. Investment in shortcut systems is simply shortsighted.

There’s another downfall to builder-specific control short cuts. These builders will only supply what they think is useful. What they have on the shelf is what you get. This approach makes the assumption that these builders know exactly what your shop needs, which of course is impossible for every shop in existence. Plus, your needs will likely change over time. If you decide you want customization, you must go back to the builder and request it. Okuma’s App Store provides a more dynamic environment that aggregates machine tool apps from many providers (not just the builder) and allows for individual customization whenever and however the user decides.

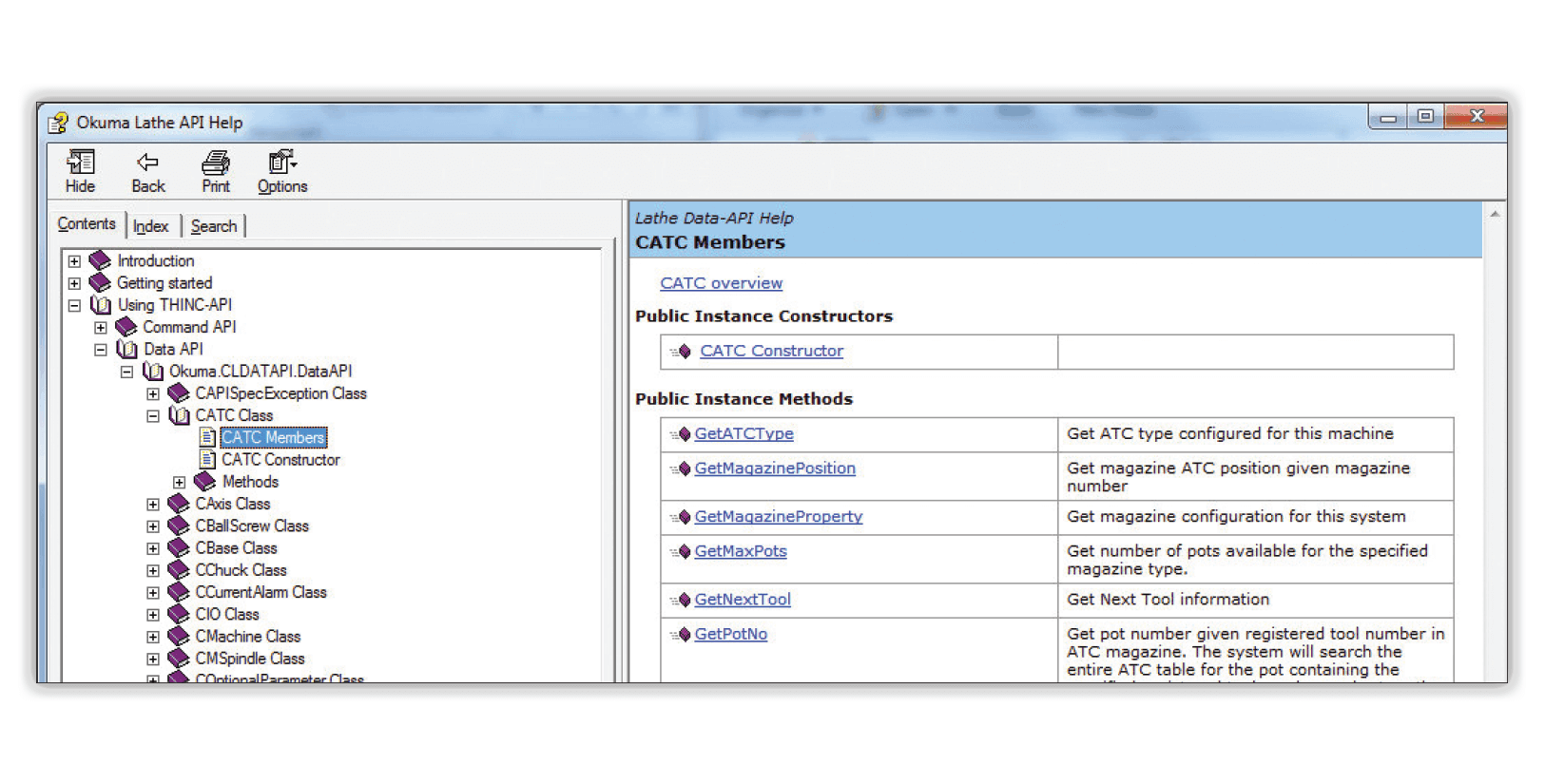

CONNECTIVITY – ACCESS TO THE API

Apps should also be able to be connected with other programs used in the shop, such as Word or Excel files, CAD CAM software, and ERP/business management systems. This is made possible by allowing access to the machine tool’s API, or Application Program Interface (see Figure 2). This interface allows the machine tool and the application software to communicate and share data. Any machine tool user has this data, but the key is being able to access it. Once data is gathered, it can be analyzed and appropriate action can be taken to optimize processes. If users don’t take advantage of the opportunities that lay hidden in their data, progress cannot be achieved. Machine tool apps used on an open architecture platform make this easy for users by digging into data and delivering useful functionality. Additionally, the use of MTConnect as a communication tool is growing. Okuma’s API fully supports and integrates with MTConnect and an MTConnect agent/adapter is available in app form.

SURPRISINGLY, MACHINE TOOL APPS ARE NOT “NEW”

Okuma laid the foundation for machine tool apps in 2004 with the release of the THINC-OSP, the industry’s first open architecture control. This “openness” was (and still is) revolutionary. Since 2004 Okuma has implemented numerous apps that customize our CNC machines to solve a customer’s problem.

USE OF MACHINE TOOL APPS IS GROWING

While having the ability to create apps has been around for a while, the credit goes to Android and Apple for creating awareness and understanding for what this means. It means you can go to an App Store and download useful apps that have already been created. Many of them are free. You can read reviews and get insights about how each app works for other users. Developers can also upload apps they’ve created and shared. Use of apps is growing in the manufacturing industry, and apps will become just as indispensable in machine shops as they are in our everyday lives.

PUTS THE POWER IN YOUR HANDS

Many people wonder how to get started with machine tool apps. The easiest way is to download apps that have already been created and experience the results. But the real advantage comes when you customize an app that no one else has, for your own unique requirements. There are many ways to do this. Perhaps you have internal IT specialists who can be tasked with creating your unique machine tool apps. You may have savvy operators with programming experience who can do this, or even a family member who’s familiar with app development. Another option is to simply contact your distributor or Okuma representative, who will be happy to locate a suitable development resource. For someone with development experience this is a relatively simple process with big rewards for you.

You gain an immediate productivity advantage while raising the bar beyond your competitors’ reach.

The possibilities are limited only by your imagination. The best starting point is your unique idea about what you need to improve in your machine shop. With an open architecture control, you can create apps that enhance productivity while simplifying your life. Machine tool apps put the power in your hands, to do more than you ever thought possible with your machine tool.